Various conditions such as material, bore diameter, pitch and punching specification are required depending on intended purpose. To need the needs, we produce satisfying products for customers by developing various production equipment such as cutting-edge equipment that is necessary for molds. We will be waiting for your order with a system to respond immediately that other companies do not have.

Materials

Cool rolling & hot rolling steel plate / Various surface treatment steel plates / High-tension steel plate / Stainless steel plate / Aluminum / Colored aluminum / Duralumin / Copper / Brass / Phosphor bronze/ Nickel / Titanium / Various resin plates / Various plates such as fiber, rubber and hard board etc.

Material form

We handle sheet plate and coil.

Plate thickness

As for steel plate, stainless, aluminum, copper and brass etc., based on the standards of JIS.

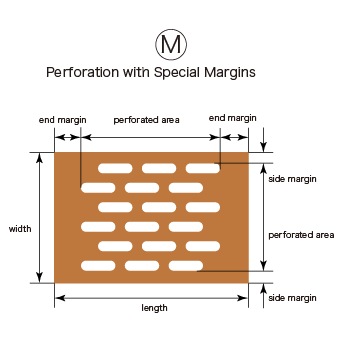

Please designate dimensions of both ends of a plate in case of ordering block punching and marginal punching. And please designate punching are and marginal dimensions in case of a block plate.

And in case of variant shapes such and circle and trapezoid etc., a difference in level of 90° along with circle and variant shapes occurs. In this case, normally we scrub a square shaped plate in circular and make as circle after punching. In case of variant shapes such as trapezoid etc., it is possible to punch at a plate shape.(Reference Picture L)

About top and end of hound’s tooth punching

Normally a hound’s tooth-shaped mold becomes an even number. In this case, houndstooth shape of punching end and shapes of both ends become asymmetry. So in case of finishing at same position and shape, we cover at a different process.

About punching area

Please refer to Drawing M. In this case, please designate a dimension from center of the first hole and center of the last hole or from end of a hole to end of a hole.

Round hole

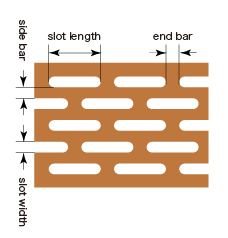

Long hole

Angle hole

Square holes, Series

Rate of hole area is an important factor of usage function of a punching-wire etc. Calculation equations of rate of hole area based on hole shape, pitch, hole arrangement, angle and punching area are as below.

D/Hole diameter l P/Center pitch l P1/When the center pitchof straight horizontal and vertical differ.